分類導航

推薦新聞

聯(lián)系我們

濟南潤鑫數(shù)控機械有限公司

聯(lián)系人:王經(jīng)理

服務熱線:13954172788

聯(lián)系地址:濟南市104國道邵西潤鑫工業(yè)園

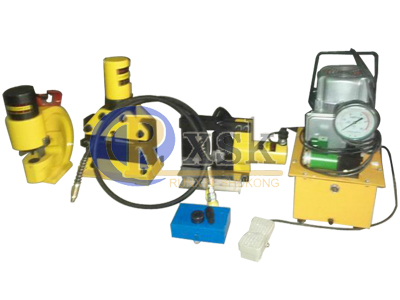

銅排加工機安裝光柵尺取代傳統(tǒng)的傳感器

一般用在銅排加工機上安裝一款光柵尺,取代傳統(tǒng)的定位塊和光電傳感器,其主副尺相對移動之距離可通過數(shù)據(jù)線傳輸至可編程控制器(PLC)。根據(jù)光柵尺直線移動距離與要成型之零件的折彎角度之間的數(shù)學關(guān)系進行PLC編程。

Commonly used in copper platoon processing machine installation a grating ruler, to replace the traditional positioning block and the photoelectric sensor, its main 'relative motion of the distance by cable to the programmable controller (PLC). According to the grating ruler linear movement of distance and molded parts the mathematical relationship between the bending Angle of PLC programming.

銅排加工機:http://freshscreen.cn

Copper platoon processing machine

當用戶輸入要求折彎的角度,PLC可計算出光柵的理論位移。當折彎油缸動作,帶動光柵尺付尺動作,光柵尺之讀數(shù)(即主付尺相對移動之距離)與光柵的理論位移一致時,PLC會命令電磁閥反向動作,折彎油缸返回,完成折彎成型動作。

When the user input requirements of bending Angle, the PLC can calculate the displacement of the theory of grating. When bending cylinder action, lead pay scale grating ruler, the grating ruler reading (i.e., the main pay scale of relative movement distance) consistent with the theory of grating displacement, the PLC will command the electromagnetic valve reverse action, bending cylinder returns, complete bending forming.

由此可見,采用PLC加光柵尺構(gòu)成的閉環(huán)控制,銅排加工機只需更改內(nèi)部程序即可實現(xiàn)不同的折彎角度及折彎生產(chǎn)過程自動化,控制系統(tǒng)具有較高的智能化、柔性化功能,而且相比采用數(shù)字控制的折彎機而言,又具有良好的性價比。

Thus, PLC and grating ruler constitute a closed loop control, copper platoon processing machine can be realized only need to change the internal program of bending Angle and bending of the production process automation, control system with high intelligence, flexible function, and compared with adopting digital control bending machine, and has good cost performance.

上一條:箔繞機長久高效的運行保持其安全性

下一條:母線加工機沖、剪、折工藝介紹

相關(guān)文章 / Recommended news

相關(guān)產(chǎn)品 / Related products

X

13954172788

13954172788